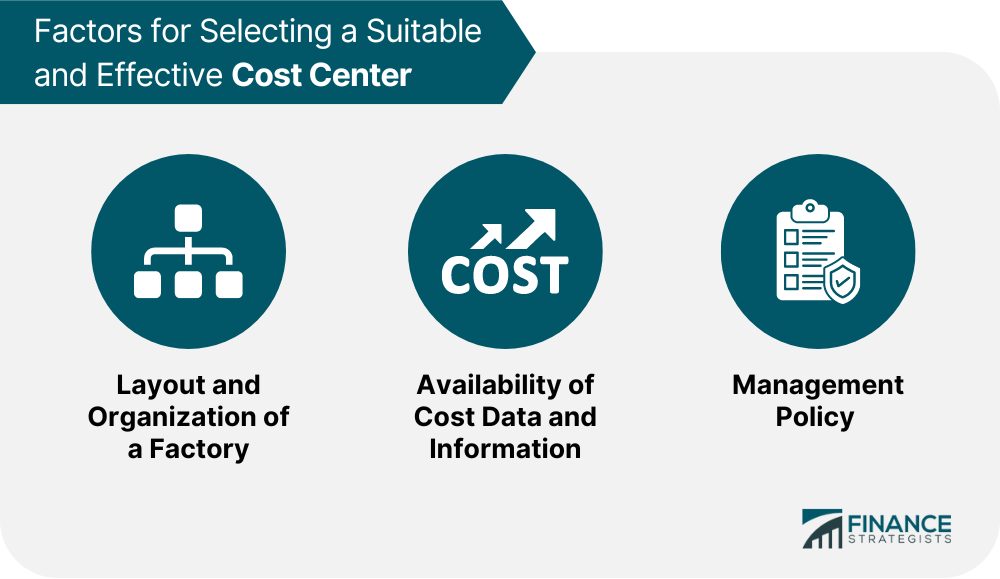

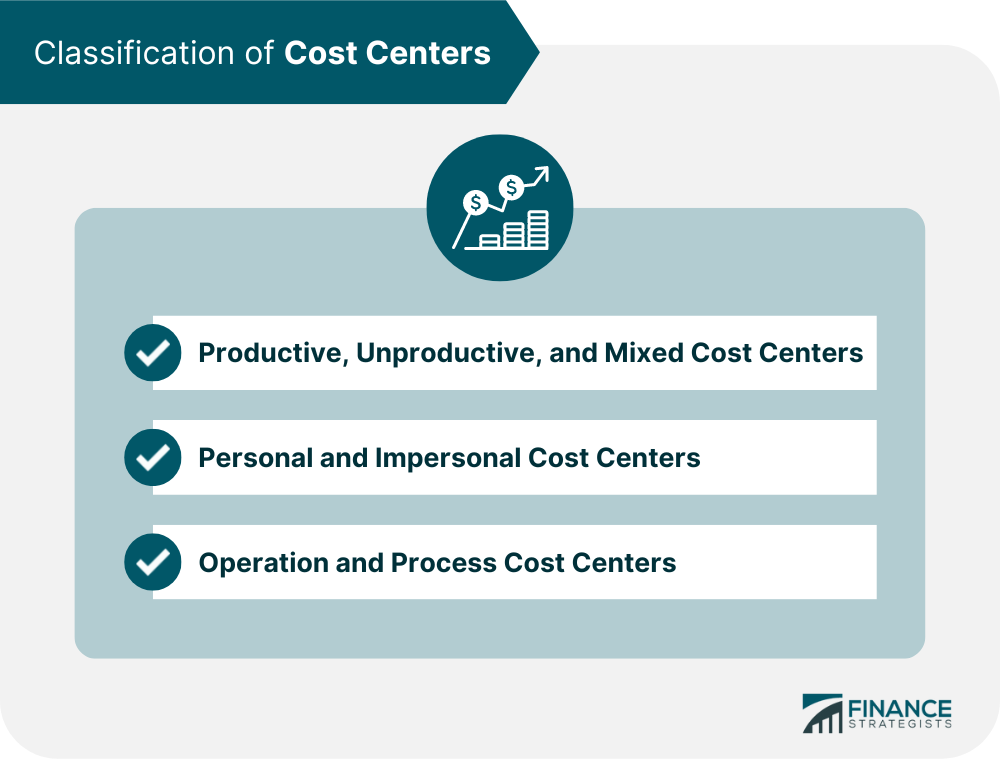

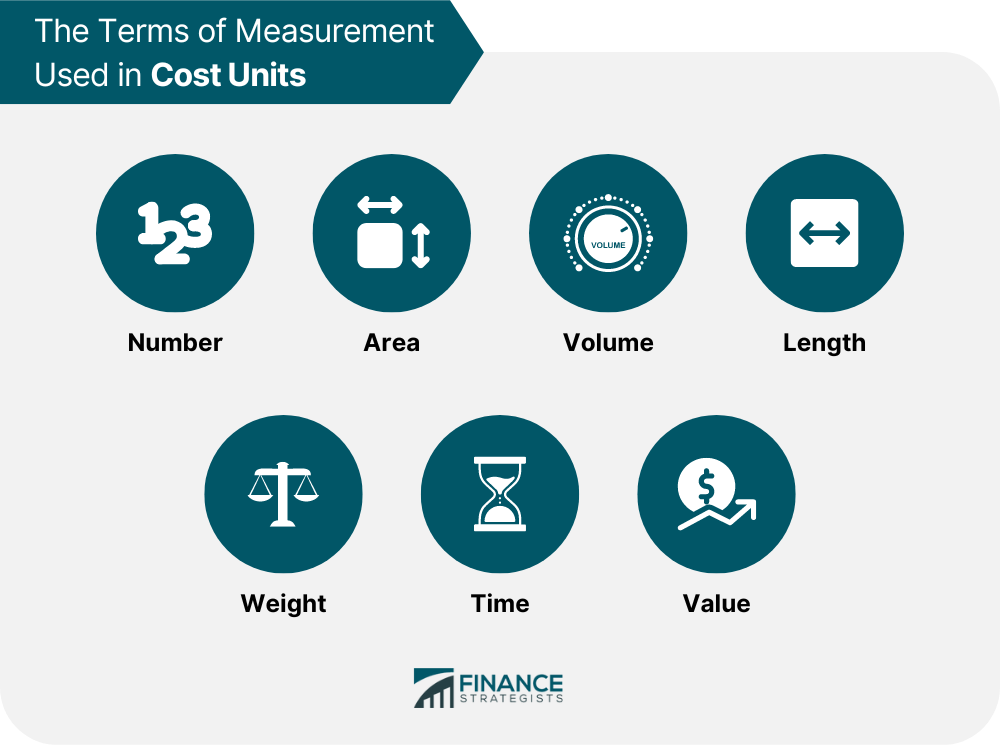

In cost accounting, costs are understood in terms of cost centers and cost units. With this in mind, it is essential to know what these terms mean. The Institute of Cost and Management Accountants (ICMA), which is based in London, defined a cost center a location, person, or item of equipment (or a group of these) for which costs may be ascertained and used for the purposes of cost control. That's to say, a cost center refers to any place, person, machine, section, part, activity, or function within an organization or undertaking by which costs are collected or accumulated, and to which costs are allocated. Given the above, a cost center is, therefore, a natural division of an undertaking that helps to measure and understand operational costs and apply costs to products. A cost center in a company is formed by considering the convenience of cost accumulation, comparability, and cost control. If costs are accumulated for a person, machine, or department, then this entity will be treated as a cost center. In an undertaking, cost centers may be divided into two parts: A production cost center refers to a cost center that is engaged in regular production (e.g., converting raw materials into finished products). A service cost center is a center that is not engaged in regular production, but which assists the production cost centers in implementing their activities (e.g., store department, personnel department, or maintenance department). Cost centers can also be divided into operation cost centers and process cost centers, as well as personal cost centers and impersonal cost centers. Operation cost centers are cost centers that consist of machines and/or persons carrying out similar operations, while a process cost center is one that consists of a specific process or a continuous sequence of operations. A personal cost center is a cost center that consists of a person or group of persons (e.g., departmental foreman, salesman, supervisor, and factory manager). An impersonal cost center refers to a cost center that consists of a location, item of equipment, or a group of these (e.g., machines, departments, and vehicles). The selection of a suitable cost center depends on several factors, including: Cost centers can be classified under the following three broad areas: Factories might choose productive cost centers whereas an administrative wing might choose an unproductive cost center. Similarly, a tool department may choose a mixed cost center. When a plant or machine is taken as a unit, it is an impersonal cost center; when a person or group of persons are taken as a unit, the personal cost center is implied. According to the Institute of Cost and Management Accountants, "Impersonal cost center consists of a location of item of equipment whereas personal cost center consists of a person or a group of persons." According to the Institute of Cost and Management Accountants, the "operation cost center is a center which consists of those machines and/or persons which carry out the same operations." By contrast, the "process cost center is a cost center which consists of a continuous sequence of operations." After costs have been ascertained, accumulated, classified, and recorded, they must be related to a convenient measure of the quantity of the product or service. This measure of the quantity of a product or service is known as the cost unit. A cost unit is defined as "a unit of quantity of product, service, or time (or a combination of these) in relation to which costs may be ascertained or expressed." In other words, a cost unit is a standard or unit of measurement of the goods manufactured or services rendered. A cost unit may be expressed in terms of number, length, area, weight, volume, time, or value. A unit of cost must possess the following characteristics: Cost units can be categorized as follows: Simple Unit: These use a single standard or unit of measurement of the goods manufactured (e.g., per piece, per kilogram, per quintal, per ton, per gallon, or per meter). Composite Unit or Complex Unit: These combine two simple units (e.g., per passenger-kilometer, per ton-kilometer, or per kilowatt-hour). The terms of measurement used in cost units are: Cost units are always selected carefully based on the nature of business operations. For instance, the cost unit of steel is naturally ascertained in terms of per ton. Similarly, the cost unit of carrying a passenger by a transporter is naturally ascertained in terms of the distance traveled in kilometers. The following are examples of cost units applied in different industries: The main points of difference between cost centers and cost units are summarized as follows:What Is a Cost Center?

Factors for Selecting a Suitable and Effective Cost Center

Classification of Cost Centers

What Is a Cost Unit?

Characteristics of a Cost Unit

Types of Cost Units

Differences Between Cost Center and Cost Unit

Cost Center and Cost Unit FAQs

It defined a cost center a location, person, or item of equipment (or a group of these) for which costs may be ascertained and used for the purposes of cost control. That’s to say, a cost center refers to any place, person, machine, section, part, activity, or function within an organization or undertaking by which costs are collected or accumulated, and to which costs are allocated.

It is production cost centers and service cost centers

A production cost center refers to a cost center that is engaged in regular production (e.g. converting raw materials into finished products).

A service cost center is a center that is not engaged in regular production, but assists the production cost centers in implementing their activities (e.g. store department, personnel department, or maintenance department).

A cost unit is defined as “a unit of quantity of product, service, or time (or a combination of these) in relation to which costs may be ascertained or expressed.” In other words, a cost unit is a standard or unit of measurement of the goods manufactured or services rendered.

True Tamplin is a published author, public speaker, CEO of UpDigital, and founder of Finance Strategists.

True is a Certified Educator in Personal Finance (CEPF®), author of The Handy Financial Ratios Guide, a member of the Society for Advancing Business Editing and Writing, contributes to his financial education site, Finance Strategists, and has spoken to various financial communities such as the CFA Institute, as well as university students like his Alma mater, Biola University, where he received a bachelor of science in business and data analytics.

To learn more about True, visit his personal website or view his author profiles on Amazon, Nasdaq and Forbes.